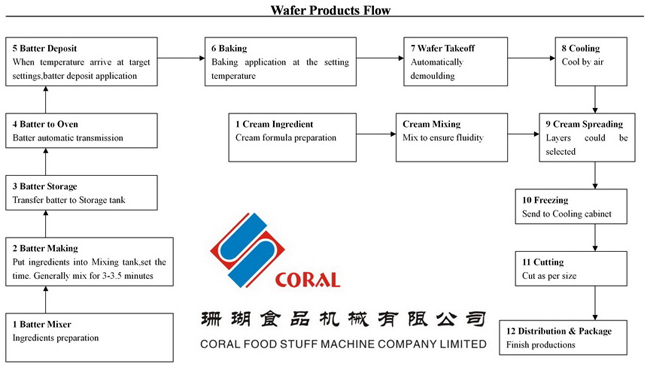

Lines for baking flat wafers with cream layers

Automatic production line for baking wafers with cream layers consists of baking oven, cooling tower which cools down the freshly baked wafer sheets and prevents them from deformation, cream spreading machine, cooling cabinet, packing machine, batter mixer, cream mixer and wafer smash machine. Additionally for products covered in chocolate the line can be enlarged by a chocolate coating machine and a cooling cabinet.

The whole line was designed and manufactured in order to equal in quality and functionality with the best devices from international companies. It’s characterized by a high efficiency, thorough workmanship, compact construction, relatively small space occupied, low energy consumption and simple operation as well as effortless maintenance.

German motors SEW are applied as drives, the bearings are from French SKF. The operational-control system which steers the whole process is based on PLC drivers.

Efficiency:

| Electric oven / Plates amount | 27 | 33 | 39 | 45 | 51 | 63 | 75 |

| Energy consumption (kW) | 120 | 140 | 160 | 180 | 200 | 240 | 280 |

| Efficiency (kg/h) | 83 | 125 | 145 | 166 | 187 | 250 | 312 |

| Gas oven / Plates amount | 27 | 33 | 39 | 45 | 51 | 65 | 75 |

| Energy consumption (kW) | 13 | 15 | 19 | 23 | 27 | 32 | 37 |

| Efficiency (kg/h) | 83 | 125 | 145 | 166 | 187 | 250 | 312 |

Characteristics:

- Fully automated process, stable work and device’s efficiency, simple operation and easy maintenance

- All drivers, bearings and electrical parts come from well known producers or from reputable Chinese companies

- Well-thought-out order, compact structure and distribution of components, compact size

- High level of final product collection (not less than 98 %), equally heated on the whole surface and unanimously colored wafer sheets

- Custom-designed machinery guarantees low energy consumption and enables energy savings while production as well as pollution’s reduction

- Material from which the machinery are made of comply with food hygiene standards-all machinery parts which have contact with the food products are made of stainless steel

- Wafer’s shape, grind’s type and size are optional according to customer’s needs

Technical parameter’s of the complete line

|

Model plates |

Air compressor, Consumption |

Baking plate’s size (mm) |

Size after the external cut (mm) |

Dimentions (L. × W. × H.): (m) |

Weight (tons) |

| 27 |

0.9 M3/Min 0.8Mpa |

470×325 470×350 500×350 |

455×315 455×340 485×340 |

23.6×2.1×2.5 | 15.0 |

| 33 | 24.7×2.1×2.5 | 15.5 | |||

| 39 | 25.8×2.1×2.5 | 16.0 | |||

| 45 | 27.0×2.1×2.5 | 19.0 | |||

| 51 | 28.0×2.1×2.5 | 21.0 | |||

| 63 | 30×2.1×2.5 | 25.6 | |||

| 65 | 31.0×2.1×2.5 | 26.0 | |||

| 75 | 32.7×2.1×2.5 | 29.0 |

Wafer machine layout

Component parts of the automatic line for baking flat wafers with cream

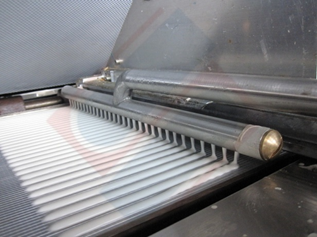

1. Baking oven

General characteristics:

- Fully automatic and controlled at each baking stage

- Electric or gas heating

- Baking plates are manufactured from a high quality grey iron which is characterized by long durability and ensure equal heating which profits in equal color of the freshly baked wafers

- Double enclosure from the stainless steel prevents from warmth lost and ensures a smooth and esthetic appearance as well as uncomplicated cleaning

- Control panel: touch screen from Mitschubishi (Japan)

- Built-in wafers’ waste cleaning device

- Range of wafer thickness: 2,0 mm-3,2 mm

- Baking temperature: 180 °C

- Baking plates amount to choose: 27, 33, 39, 45, 51, 63, 75

Efficiency

| Type: electrical / plates amount | 27 | 33 | 39 | 45 | 51 | 63 | 75 |

| Energy consumption (KW) | 120 | 140 | 160 | 180 | 200 | 240 | 280 |

| Daily capacity (kg/h) | 83 | 125 | 145 | 166 | 187 | 250 | 312 |

| Type: gas / plates amount | 27 | 33 | 39 | 45 | 51 | 65 | 75 |

| LPG (kg/h) | 13 | 15 | 19 | 23 | 27 | 32 | 37 |

| Daily capacity (kg/h) | 83 | 125 | 145 | 166 | 187 | 250 | 312 |

Oven’s basic technical parameter’s

|

Model/ Plates amount |

Compressed air consumption |

Baking plate sizes (mm) |

Dimensions after wafer cutting (mm) |

Dimensions L. × W. × H. (mm) |

Weight (kg) |

| 27 |

0.9 m3/min 0.8Mpa |

470×325 470×350 500×350 |

455×315 455×340 485×340 |

5600×2.1×2.5 | 7800 |

| 33 | 6725×2.1×2.5 | 9000 | |||

| 39 | 7865×2.1×2.5 | 10500 | |||

| 45 | 9000×2.1×2.5 | 12000 | |||

| 51 | 10140×2.1×2.5 | 14000 | |||

| 63 | 12580×2.1×2.5 | 18000 | |||

| 65 | 12840×2.1×2.5 | 18580 | |||

| 75 | 14730×2.1×2.5 | 21000 |

2. Cooling tower

It is used for cooling down the freshly baked wafers and prevents wafers from damaging as well for transportation wafers to the cream spreading device.

- Made from stainless steel according to hygiene standards and security rules

- Device’s speed regulation and control

- Cooling time: 3 minutes

- Dimensions (L x W x H): 2600 mm x 1080 mm x 2430 mm

- Power supply: 0,55 kW

3. Cream spreading device: device that spreads cream on the wafer sheets

This device enables automatic dosage of the cream and guarantees evenly spread onto the wafer sheets. Each wafer with a cream layer is moved towards belt conveyor. The tank is equipped with heating system which enables heating of the cream, keeps its temperature and maintain the cream in a liquid consistency.

It is possible of fixing 2 or 3 nozzles which dose different types of a cream.

- Frame and cover: made out of stainless steel

- Motor and reducer: SEW (Germany)

- Converter: VLT Danfoss

- Control panel: Mitsubishi (Japan)

- Dimensions (L x W x H): 2485 x 1200 x 1730 mm

- Power supply: 2,92 kW

4. Device picking wafer sheets

This device automatically detects if each wafer sheet which comes through is baked correctly. In case if a damaged wafer occurs – such wafer is automatically removed by the device.

- Material: stainless steel

- Motor: SEW (Germany)

- Dimensions: ( L. x W. x H.) 2200 mm x 1060 mm x 840mm

- Power supply: 0,18 kW

5. Cooling cabinet

This device quickly and equally lowers the temperature of wafers layered with cream what enables easier cutting and guarantees crunchiness and delicate taste as well as long freshness.

- Temperature of cooling: 8-12 °C (min. -5 °C)

- Frame: stainless steal

- Cover: stainless steel X5CrNi18-10

- Isolation: polyurethane with thickness of 150 mm

- Cooling element: cooling by water or air

- Motor: SEW (Germany), compressor: SANYO (Japan)

- Electromagnetic valve: Caste (Italy), decompress valve: Danfoss (Denemark)

- Dimensions: (L. x H. x W.) 3700 mm x 1200 mm x 2612 mm

- Power supply: 8,53 kW

6. Wafer cutting device

Cutting wafer sheets according to the size demanded by the client. The cutting unit can be wire or a knife.

- Material: frame made out of stainless steel

- Cover: made out of stainless steel X5CrNi18-10

- Motor: SEW (Germany)

- Programming: Simens (Germany)

- Switch: Schneider (Germany)

- Dimensions (L. x W. x H.) 1542 mm x 2100 mm x 1100 mm

- Power supply: 0,75 kW

7. Distribution device

This device is used for further transportation of the already cut, single wafers packets towards next device.

- Material: stainless steel

- Conveyor belt made out from polyurethane

- Net made out from stainless steel

- Motor: SEW (Germany)

- Dimensions: (L. x W. x H.) 2300 mm x 1400 mm x 820 mm

- Power supply: 0,18 kW

8. Cream mixer with storage barrel for cream and automatic cream transportation system

This device is used to for preparation of cream for wafers while mixing sugar, shortening and other cream’s ingredients. The mixer allows to receive a very exact mixed cream as well as cream’s volume increase. The mixed cream mass is applied automatically into the cream spreader device.

- Material: stainless steel

- Motor: SEW (Germany)

- Pump: Lobe (Germany)

- Speed and mixing duration: adjustable

- ‘Water jacket’ control system

- Volume of batter tank: 200 l

- Volume of batter storage barrel: 300 l

- Dimensions (L. x W. x H.) 1800 mm x 900 mm x 1900 mm

- Power supply: 9.9 kW

9. Batter mixer for wafer’s batter

The device consists of two barrels made out from stainless steel: a container for mixing and a container for storage of the mass. It is equipped with steering panel with water control, time of mixing and transportation of the batter into the oven for wafers baking.

| Device | Batter mixer SH-DJ |

| Material | X5CrNi18-10 |

| Electronics | Schneider (Germany) |

| Length | 1860 mm |

| Width | 900 mm |

| Height | 1600 mm |

| Power Supply |

5.5 kW (3~N 380V 50Hz) |

| Pump | 4 m³/h, 8mH2O |

10. Chocolate coating machine

| Device | SH-QKL |

| Material | X5CrNi18-10 |

| Lenght | 1600 mm |

| Width | 1500 mm |

| Height | 1900 mm |

| Electric energy consumption | 5.58 kW (3~N 380V 50Hz) |

| Pump | 0.5 m³/h; 0.8Mpa; 48 r/min |

11. Cooling tunnel

| Model | Voltage | Cooling | Cooling temperature °C | Total power |

Belt’s width |

Dimensions |

| QKL600 |

380V 50Hz |

20HP | 2-10 | 22.08 | 600mm | 23032×1200×1865 |

| QKL900 | 2-10 | 22.08 | 900mm | 23032×1500×1865 |

12. Wafer Smash Machine

Smash the wafer’s waste for recycling

Specificaions:

- Frame, Barell’s exterior and equipment (instrumentation): stainless steel

- Motor: SEW

- Power: 3,0 kW

- Dimensions: 690 x 610 x 1250 mm

13. Chocolate Grinder

This machine is used to grind chocolate ingredients, set with electric heating system and automatic temperature control.

Specificaions:

- Frame, tank’s body: stainless steel

- Max capacity:500 kg

- Main motor power::15 kW

- Grinding finensess: 20-25 μm

- Main shaft speed: 33 rpm

- Dimensions(L.xW.xH.): 2500x1550x1370 mm

- Weight: 2800 kgs

14. Automatic Stacking and Packing System

This unit is applied for automatically packing different wafer products. Various of package designs are available for options as per clients demand.

Wafer Smash Machine

Firma Kocuła

ul. Wiśniowa 5

Mokronos Dolny

55-080 Kąty Wrocławskie

Poland

tel.: +48 71 363 50 15