Machines for baking flat wafers-rectangular, round wafers and altar bread type

Automatic machines

Automatic machine type WPA12 for one-time baking of 12 pieces of wafer sheets 280x280x6

• capacity: 420 pieces of wafer sheets per hour

• installed power: 36 kW

• energy consumption: ~ 30 kW/hour

• dimensions: length 2.8 m, width 1.8 m, height: 1.7 m

Kocula automatic machine for baking flat, shaped wafers of the shell and half-ball type.

Automatic 6-iron machine for baking round wafers

Information:

Automatic 6-iron machine for baking round wafers

Capacity: 200 pieces per hour

Installed power: 15 kW

Automatic machinery for baking flat wafers with a size of 420 x 280.

Information:

An automatic machinery by Kocuła for baking flat wafers with a size of 420 x 280 with the possibility of breaking each leaf, without cutting it into 6 pieces with dimensions of 140 x 140. Efficiency: 120 pieces of waffle leaves, dimensions 420x280 per hour(720 wafers in size 140x140mm per hour). Installed power: 19 kW.

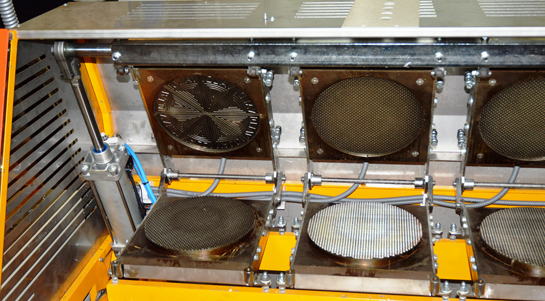

Machineries for baking flat wafers-round and rectangular.

4-baking plates set for baking flat wafers equipped with automatic closing and opening of the baking plates, cutting of the wafer’s excess and removal of the wafers.

Efficiency: 120-160 wafer sheets/hour

Power installed: 10,5 kW

Necessity for compressed air intallation: 80 l/min.

Machinery’s dimensions: 2,4 x 1,8 x 1,8 m.

Mechanized machinery for baking flat wafers

Kocula company enlarged its offer for small and medium size companies by mechanized machineries for baking flat wafers, which are equipped with automatic opening and closing system. Remain of the operations meaning dosage of the batter, taking of freshly baked wafers- are done manually. Automatisation of the opening and closing of the baking plates eliminates the biggest physical effort done by the machinery's operator. Mechanized machineries are equipped with housing (enclosure) and with light curtain which guarantee safety of the machinery's operator by immediate blockade of the opening and closing when the safety zone was entered.

This mechanized machineries need connection of the compressed air. They might be manufactured as a fully new equippment or we can use the existing baking plates and the stearing panel (which were used in the manually operated machines of the Kocula company).

Hand operated machines

Manufactured by our firm machinery for baking flat wafers (including square, rectangular as well as round wafers) is, in principle, designed for small and medium firms. As the rule they are made as four-iron sets. It means, that there are four independent irons, mounted in the common base (frame); each iron is designed for baking of one wafer sheet.

Manufactured by our firm machinery for baking flat wafers (including square, rectangular as well as round wafers) is, in principle, designed for small and medium firms. As the rule they are made as four-iron sets. It means, that there are four independent irons, mounted in the common base (frame); each iron is designed for baking of one wafer sheet.

In the front of the base the tank for dough is placed, together with the mechanical filling device which enables with the single hand motion, to fill the measured quantity of dough in the given spots on each iron simultaneously. Each four-iron set is equipped with the temperature control (separately for each iron) and baking time control (with audible-optic signal of the end-of-baking).All control elements and electrical protections are placed in the separate, freestanding console. All electrical and electronic equipment comes from verified producers and guarantees high durability, reliability and safety. Matrices are made of high quality cast iron, base (frame) is made of galvanized steel and other elements are made of acid resistant steel or chromium plated steel.

Applying of temperature control and baking time control and mechanical filling device together with precise manufacture of irons enables to obtain a maximum quantity of wafer from the given quantity of flour (we can receive about 800 kgs wafer from 1 t of flour). Machine can be run non-stop, i.e. 24 hours a day.Efficiency from one machinery (depending on the wafer's thickness) is ~ 130 wafer sheets per 1 hour.

Firma Kocuła

ul. Wiśniowa 5

Mokronos Dolny

55-080 Kąty Wrocławskie

Poland

tel.: +48 71 363 50 15