Line for soft wafer production

Highly efficient fully automatic line from Coral Company for soft wafer production.

The whole process is fully automatic, starting from batter mixing up to cooling down the final product.

| Efficiency | 8.0 tons/24 hours. |

| Electric energy consumption | 26.79KW (3~N 380V, 50HZ) |

| Line’s dimensions | 21.0m×8.0m×2.5 m |

| Weight | 23 tons |

| Amount of final product | ≥98% |

| LPG Consumption | 32.0 kg/h |

| LNG Consumption | 44.1 m3/h |

| Heating plates sizes | 470×325 mm |

| Baking time | 180 s |

| Cooling | 30 HP |

| Coolant | R22 |

Component parts of the soft wafer baking line:

1. Baking oven

Control panel: touch screen (Mitsubishi, Japan)

- Controlling possibility of the programmed - and actual - temperature on the touch screen

- Electronic indicator of temperature- and wafer amount produced per minute

- Display/control/adjustment of the transportation speed and disposition

- Servo mechanisms dispose batter on each baking plate

Oven’s baking system:

- Upper and lower high voltage burners which ignite itself automatically

- Gas pressure’s safety-valve, air filters, gas pressure and air switch, manometer and shut-off valve

- Fan leading the air into the combustion chamber and into the mixture

- Automatic control system with an infrared sensor

- Raytex probe measuring temperature on the baking plates

| Device | Line for soft wafers |

| Lenght | 12840 mm |

| Width | 2300 mm |

| High | 2500 mm |

| Weight | 19000 kg |

| LPG’s consumption | 32 kg/h |

| Electric energy consumption | 17.93 kW (3~N 380V 50Hz) |

2. Conveyor

This device transports wafers from oven directly to the cooling station.

| Device | Conveyor SH-SS |

| Material | X5CrNi18-10 |

| Length | 2300 mm |

| Width | 680 mm |

| Hight | 2000 mm |

| Electric energy consumption | 0.18 kW (3~N 380V 50Hz) |

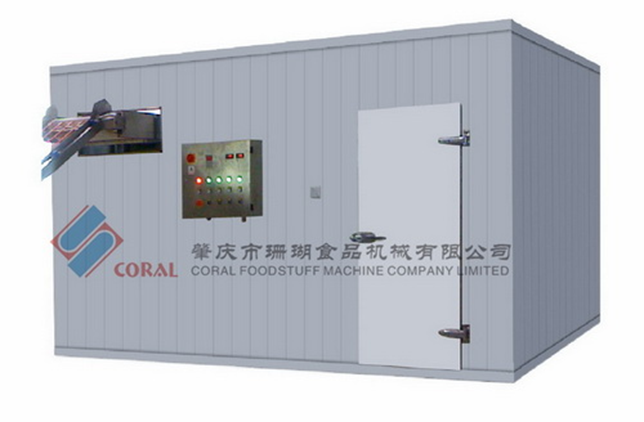

3. Spiral cooling cabinet 100M

Spiral Cooling Cabinet 100 m is used for quickly and evenly cooling of the soft wafers right after the baking process. The temperature in the cooler is even in each place. This device fulfills high demands of the hygiene and security.

| Device | Cooling cabinet 100M SH-LG |

| Isolation material | polyethylene foam PE |

| Compressor | SANYO (Japan) |

| Valve and filter | ALCO (USA) |

| Electronics | Schneider (Niemcy) |

| Coolant | 30 HP |

| Refrigerant | R22 |

| Centrifugal blower |

4.0KW 500×550 Pa 13000-18000 m³/h |

| Adjustable cooling | 0~5 °C |

| Lenght | 7245 mm |

| Width | 5500 mm |

| Height | 2400 mm |

| Power installed | 3.18 kW (3~N 380V 50Hz) |

4. Turbine mixer for soft wafer batter.

This device consists of two containers made out of stainless steel: one container is used for mixing of the batter’s ingredients, second container is used for storage of the batter.

Device is equipped with steering panel with water control possibility, mixing time and batter dosage into the oven for baking of soft wafers.

| Device | Turbine mixer for soft wafer's batter SH-DJ |

| Material | X5CrNi18-10 |

| Electronics | Schneider (Niemcy) |

| Length | 1860 mm |

| Width | 900 mm |

| Height | 1600 mm |

| Power supply | 5.5 kW (3~N 380V 50Hz) |

| Pump | 4 m³/h, 8mH2O |

Firma Kocuła

ul. Wiśniowa 5

Mokronos Dolny

55-080 Kąty Wrocławskie

Poland

tel.: +48 71 363 50 15